LYS Polychem Blog

HFFR Compound Use in the Telecom Sector: Securing Fiber Cable Production

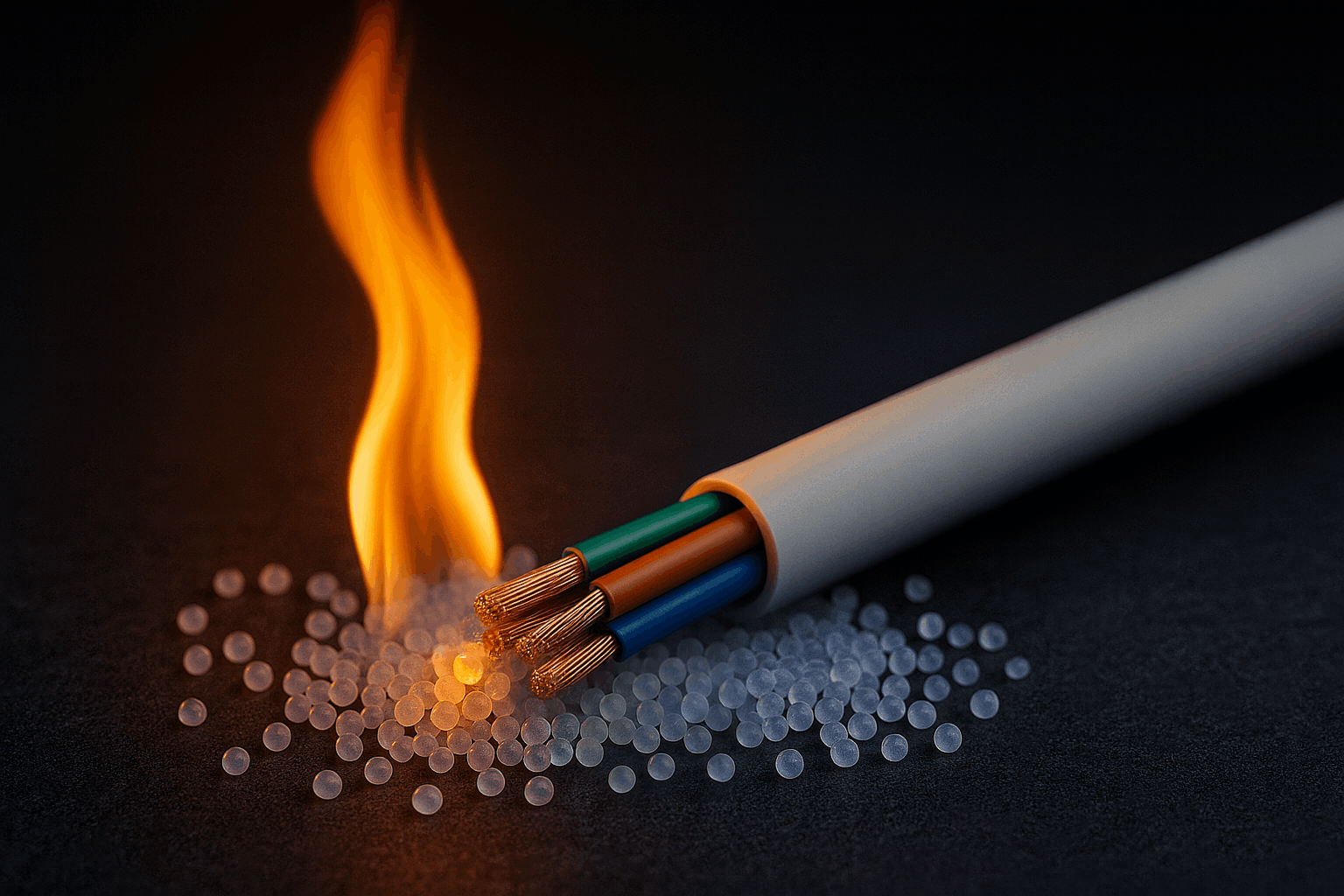

Ensuring the safety of cable production has become a top priority for manufacturers in the telecommunications sector, which expands every year. This massive industry, where cable installations, fiber optic networks, data centers, and backbone infrastructure converge, inevitably features high-density cabling environments. Consequently, the accompanying safety and sustainability standards have driven up demands for fire safety, low smoke, and low toxicity. This is where HFFR Compounds come in, emerging as a critical material, especially for indoor environments with potential fire risks.

HFFR, also known as halogen-free flame retardant plastic, offers numerous technical advantages in fiber cable production. Therefore, using HFFR compounds for cables has become indispensable for cable manufacturers.

Why is HFFR Use Essential in Fiber Cable Production?

Cables used in the telecommunications sector are typically routed through narrow ducts, trays, areas with limited ventilation, tunnels, or building risers. This cable infrastructure includes telecommunication networks, data communication cables, optical fiber cables, and hybrid power and data cables. In these high-cable-density areas, internal faults, overheating, or short circuits can lead to a fire.

In such situations, which can result in the emission of dense and toxic smoke gases, the HFFR compound is a crucial requirement for manufacturers, enabling cable systems to demonstrate risk-reducing performance. When cable jacketing and materials ignite, the release of smoke and halogen-containing acidic gas is kept at the lowest possible level with HFFR. By using these compounds, fiber cable manufacturers can greatly enhance fire safety and comply with security and sustainability procedures.

Technical Advantages of HFFR in Telecommunication Cables and Fiber Optic Production

Designed to prevent the spread of flames, the HFFR compound undergoes endothermic decomposition when exposed to heat. This change in behavior, facilitated by fillers like ATH (Aluminum Trihydrate) and MDH (Magnesium Dihydroxide), absorbs heat and generates protective charring layers. The HFFR that covers the internal and external surfaces of the cables then acts to prevent the spread of flames.

When fiber optic cables ignite due to causes like overheating, the HFFR-produced cable jackets resist the flames. This protects the cable bundle and the underlying infrastructure, thus ensuring safety.

The halogen-free performance of HFFR compound provides lower smoke density during a fire. This means less release of halogen acid gas and a minimized risk of potential corrosion during a fire. Evacuation becomes easier, visibility improves, and congestion decreases. In telecommunication systems containing sensitive electronic equipment, data, and critical network hardware, the use of HFFR is extremely critical.

Corrosive gases released by the burning of halogenated plastics in fiber cable systems have the potential to severely damage switch contacts, optical modules, and connectors. The risk of such damage and outages is reduced by using HFFR compounds. Fiber cables must maintain their integrity for an extended period during a fire for situations like evacuation and network redundancy switching. In this regard, HFFR is a vital component that ensures integrity and protects sensitive Telecom infrastructure.

Companies that produce fiber cables are certified for their compliance with environmental standards and fire safety procedures through the use of HFFR Compound. These certifications provide access to markets where halogen-free materials are mandatory. Companies using modern HFFR compounds, which are designed for excellent extrusion and processing compatibility, can achieve superior mechanical and electrical performance. Considering the importance of extrusion consistency in fiber cable production, HFFR use offers a significant advantage. Simultaneously, HFFR compound meets the requirements for flexibility, long-term durability, and enhanced safety in telecommunication and fiber cable production.

The Strategic Power of HFFR in Telecom Fiber Cable Manufacturing

There are many important safety considerations in the telecommunications sector, particularly for fiber optic and data cable applications. Cable manufacturers gain a strategic edge by using HFFR compound in insulation and jacketing. HFFR compound stands out with its flame retardancy performance, providing low smoke emission and fire safety with minimal release of halogen acid gas.

Fiber cable manufacturers can differentiate themselves by complying with regulations and standards using cables jacketed with halogen-free flame retardant plastic. This superiority is highly valuable today, especially in markets where infrastructure safety is paramount. In this context, prioritizing HFFR compounds in production creates a significant strategic opportunity for fiber cable and telecommunication cable manufacturers.

HFFR compounds, which are expected to become an important standard in the near future, will be an indispensable element for manufacturers with intensifying network infrastructure and ever-increasing expectations for fire safety.