LYS Polychem Blog

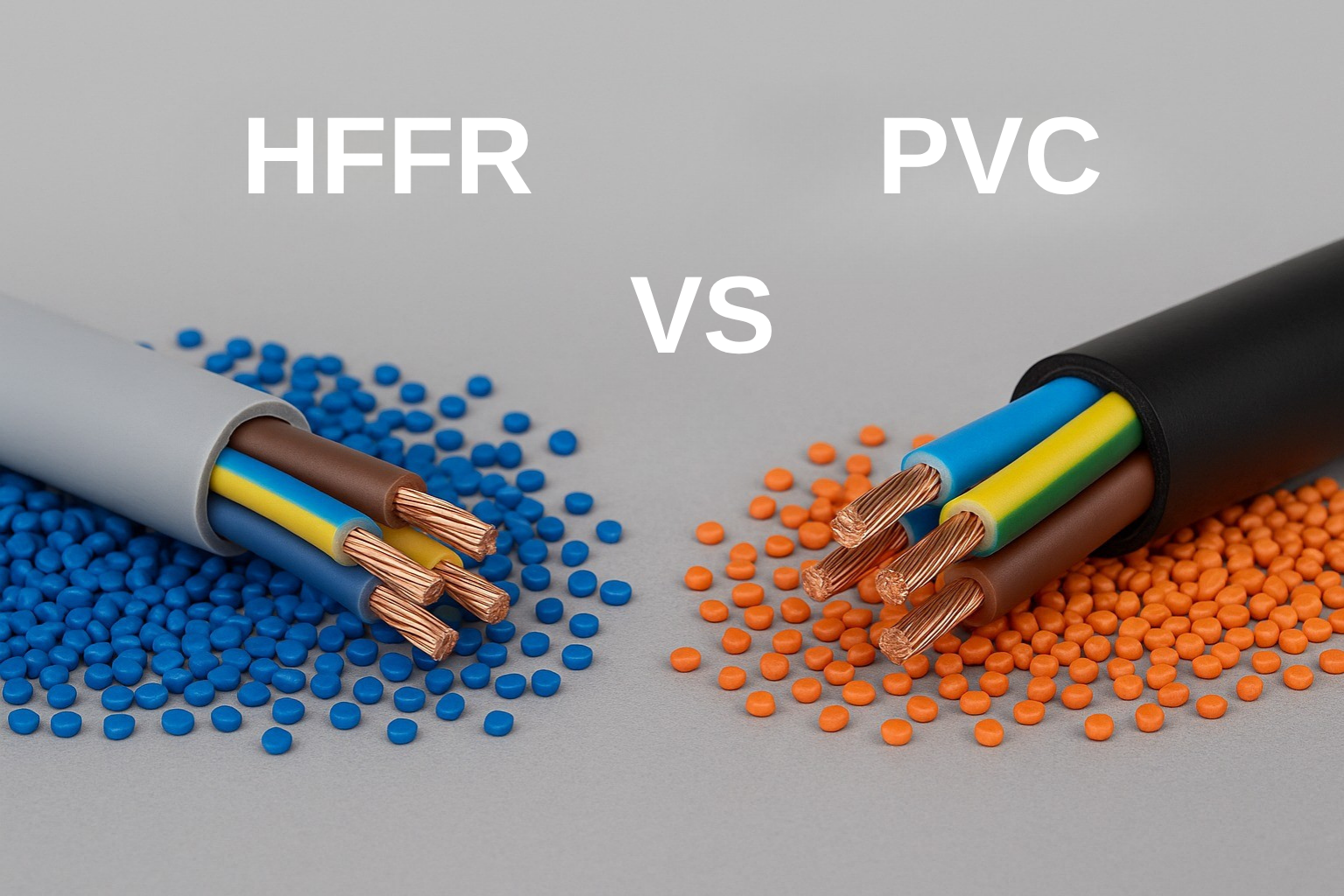

HFFR vs. PVC: A Sustainable and Safe Choice for the Future of Cables

Transitioning from PVC to HFFR: Safety and Environmental Imperatives

The cable industry has relied on Polyvinyl Chloride (PVC) as an insulation and sheathing material for many years. PVC's durable and flexible structure has made it a popular choice for many applications. However, increasing safety concerns and environmental regulations today are pushing cable manufacturers to seek safer and more sustainable alternatives. At the forefront of these alternatives are Halogen-Free Flame Retardant (HFFR) compounds. In this blog post, we will compare the HFFR compounds we produce at LYS POLYCHEM with traditional PVC, thoroughly examining the advantages and disadvantages of both materials to explain why cable manufacturers should look to HFFR for the future.

PVC: A Traditional Material and Its Critical Disadvantages

PVC is a cost-effective material that naturally possesses flame-retardant properties due to the chlorine element it contains. Because of this feature, it has been widely used in construction and industrial cable applications. However, during a fire, the chlorine in PVC's structure causes the release of toxic and corrosive gases such as hydrochloric acid as a result of combustion. These gases are extremely hazardous to human health and can also corrode metallic surfaces and electronic equipment, causing permanent damage.

The dense, dark smoke emitted by PVC cables during a fire complicates building evacuations and obstructs the visibility of rescue teams. The fact that 90% of fire accidents in 2019 were caused by electricity, and that PVC cables are used in many of these buildings, highlights the risks posed by this material in terms of fire safety. This situation poses unacceptable risks, especially for crowded and critical structures such as hospitals, schools, shopping centres and public transport systems.

HFFR: The Safe and Eco-Friendly Alternative for the Future

HFFR (Halogen-Free Flame Retardant) cable compounds, as the name suggests, do not contain halogen elements in their composition. These materials have become increasingly preferred over PVC in the last decade due to their fire safety and environmental benefits. LYS POLYCHEM's HFFR granules derive their flame-retardant properties from mineral additives such as Aluminium Trihydroxide (ATH) or Magnesium Hydroxide (MDH), rather than traditional halogen-based additives.

In the event of a fire, HFFR compounds cool and dilute the flame by releasing water vapour through an endothermic reaction. Unlike PVC, this reaction does not release toxic or corrosive gases. In addition, HFFR cables have low smoke density. This enhances life safety by keeping escape routes clear during a fire.

Cost and Processability: Common Misconceptions

There is a widespread belief in the industry that HFFR compounds have higher raw material costs than PVC and are more difficult to process. However, since conductors such as copper constitute the largest component of total cable costs, the final cost difference between HFFR and PVC cables remains negligible. Furthermore, at LYS POLYCHEM, thanks to the special binders and additives we use in our formulations, we have succeeded in bringing the mechanical performance and processability of HFFR compounds close to that of PVC, and in some cases even better. This allows cable manufacturers to transition to safer and more environmentally friendly materials without experiencing significant losses in production efficiency.

The Versatile Advantages Offered by HFFR Compounds

Fire Safety: High flame resistance and self-extinguishing properties during a fire.

Human Health and Environment: Halogen-free, does not emit toxic or corrosive gases.

Ease of Evacuation: Low smoke density does not obstruct visibility in escape routes.

Equipment Protection: Does not damage electronic devices as it does not emit corrosive gases.

Sustainability: Contains environmentally friendly additives and does not use heavy metal-based stabilisers.

The historical role of PVC in the cable industry is undeniable. However, in the modern world where safety and environmental standards are becoming increasingly stringent, HFFR compounds are unquestionably the material of the future. At LYS POLYCHEM, we invite cable manufacturers to lead this transformation. Our products are more than just a compound; they are part of a commitment to protecting human life, caring for the environment, and increasing your business's competitiveness in the European market. For detailed information about our products, please contact us via the contact form.