LYS Polychem Blog

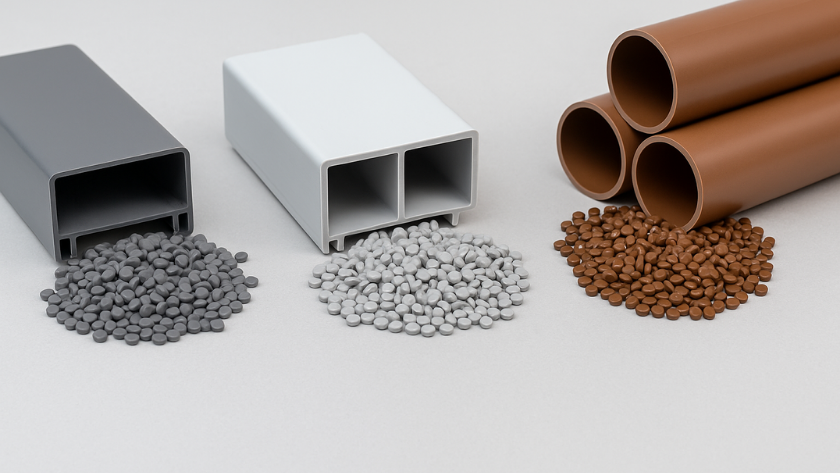

U-PVC Rigid Materials for Profile, Pipe and Duct Applications

Polyvinyl chloride (PVC) is a thermoplastic produced from vinyl chloride monomer. It is the third most widely used material in plastics production after polyethylene (PE) and polypropylene (PP). For a period after 1945, it was the most produced plastic in the world. PVC compound is used in many products that we use in everyday life, especially due to its high durability properties.

What is U-PVC?

Polyvinyl chloride (PVC) is a thermoplastic in amorphous structure.

It has a hard and brittle structure without additives. However, it can be made softer and more flexible by adding plasticizers and stabilizers.

PVC is divided into two main groups based on the amount of plasticizer it contains:

PVC-U (rigid PVC): It’s non-plasticized, has a durable construction.

PVC-P (soft PVC): It’s plasticized and is a more flexible material.

Classification is also made according to the polymerization method used during PVC production:

Emulsion polymerization (E-PVC)

Suspension polymerization (S-PVC)

Batch polymerization (M-PVC)

Properties of U-PVC Compound

PVC (polyvinyl chloride) is a durable type of plastic that we often encounter in everyday life. Due to its properties, it can be used in both rigid and flexible forms. Here are some of the main features that make PVC preferable in different areas:

It is long-lasting, resistant to impact and external factors.

It can generally be used safely at temperatures up to 60 °C.

For this reason, it is frequently preferred in cable and electrical installations.

It shows high resistance against substances such as acid, salt, alcohol and oil.

It absorbs almost no water, so it is suitable for outdoor use.

It is safe as it does not ignite easily.

It can be molded into the desired form with different production techniques (injection, extrusion, etc.).

Gives smooth surface, easy to paint, high color stability.

Thanks to these properties, PVC can be found in many products such as shutters, pipes, toys and cables.

In Which Products is PVC Compound Used?

Polyvinyl chloride (PVC) has a very wide range of uses. Rigid PVC in particular accounts for the vast majority of the processed PVC volume. Some products made from PVC are:

Window profiles, sewer pipes and shutters

Credit cards and plastic cards

Electrical engineering products: Insulation tubes, housings, cable connectors

Machine and equipment parts: Liners, hoses

Agriculture sector: Silage films, cover films

Toys: Baby toys, swimming toys, inflatables

Food technology: Conveyor belts, transparent beverage hoses

PVC can also be used as an artificial leather material for products like shoes, bags and furniture. In fiber form, it is used in technical textiles, home textiles and wig production.

Difference Between U PVC Compound and PVC Compound

UPVC and PVC granulate types are based on a similar chemical basis but differ in performance and uses. PVC compound contains plasticizers to provide flexibility in mobile applications such as cabling systems.

UPVC, on the other hand, is a plasticizer-free, rigid material with high impact strength and resistance to UV rays and chemicals. It is widely preferred for window profiles, building elements and fixed pipe systems. Both compound types offer formulation flexibility. Making the right choice when considering application conditions, mechanical requirements and environmental factors is critical for long-term performance and cost efficiency.

Can UPVC Compound be Recycled?

UPVC compound has a recyclable structure. PVC products are easy to separate and transport, especially when produced and collected in large quantities. Therefore they are suitable for mechanical recycling. Products such as window profiles, flooring and pipes are frequently recycled.

During recycling, the chlorine in PVC is recovered as hydrochloric acid (HCl) and re-used in different chemical processes.

Why Choose UPVC Compound?

UPVC stands out with its high strength and long life as well as its resistance to environmental conditions. It does not corrode, is not affected by moisture and forms a strong barrier against impacts and UV rays. Thanks to its insulation feature, it prevents energy losses and maintains structural integrity for a long time.

Rigid compounds developed by LYS Polychem offer high efficiency in sensitive processes such as extrusion and injection. It is possible to achieve the desired surface quality and dimensional stability in applications such as window profiles, cable ducts and plumbing pipes.

Customer-oriented recipes, color consistency and quality control processes from production to delivery provide the same confidence in every batch of products. If you are looking for perfect surface and high process efficiency for your project, you can choose LYS Polychem products.